A WORLD OF POSSIBILITIES

CNS is a unique best-in-class conductive additive with the following main features:

- High structure: forest of crosslinked branched nanotubes

- High purity: composed of over 97% carbon

- Ease of use: easy to handle pellet form, low dusting and fast incorporation into dispersion material

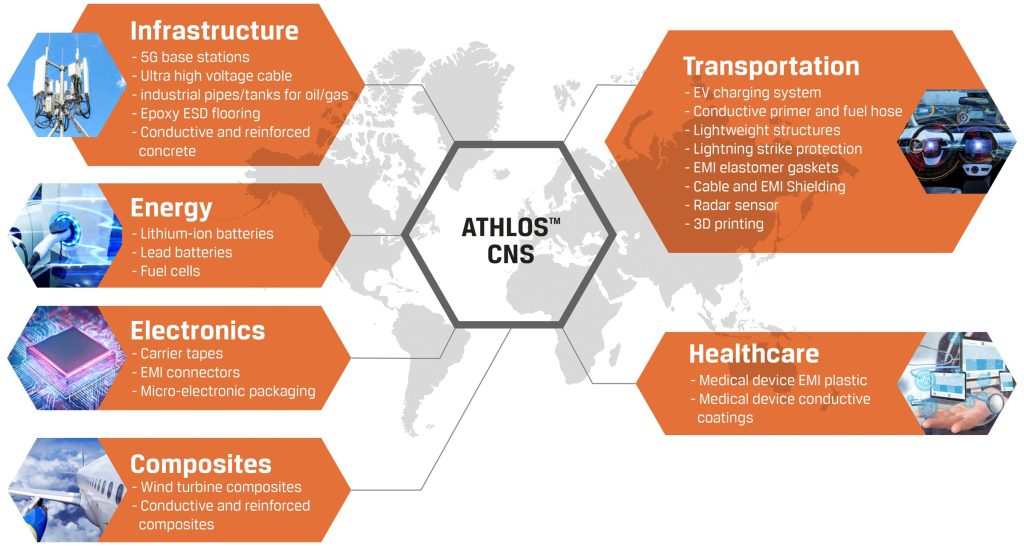

ATHLOS™ CNS delivers an exceptional combination of conductivity, electromagnetic interference (EMI) shielding, mechanical and processability strength for applications that require high-performance.

ATHLOS – CNS feature cross-linked, branched structure that enables CNS to impart key performance features such as high electrical conductivity with minimum impact on processability, low electrical percolation threshold, best-in-class EMI shielding performance, synergies with other formulation additives, reinforcement and light-weighting.

LIGHTWEIGHTING

Use of lighter materials like plastic, silicone and composites is a top priority for many applications, especially within the automotive and aerospace industries. ATHLOS™ CNS delivers EMI shielding capabilities at low loadings enabling a transition away from traditional metal solutions.

ELECTRIFICATION

ATHLOS™ CNS offers unparalleled levels of conductivity provided by a carbon-based additive. It helps products meet the most stringent conductivity requirements at a fraction of the loading of traditional additives, optimizing performance while driving reductions in cost and weight. A unique morphology of cross linked and branched carbon nanotubes allows CNS to offer enhanced conductive pathways and enable significant performance advantages vs. conventional carbon nanotubes (CNT).

MINIATURIZATION

Electronics are getting smaller, thinner and lighter. Materials and parts that comprise electronic devices need to do the same. ATHLOS™ CNS gets equivalent conductive performance versus alternative additives at a fraction of a percent loading, enabling designers to develop stronger and more conductive next generation components.

CONDUCTIVITY & ESD PROTECTION

ATHLOS™ CNS can achieve conductivity with less than 1% loading, allowing compounders to deliver improved mechanical strength while also freeing up space in their formulations to focus on other additives, enabling the flexibility required for delivering smaller, thinner and lighter conductive parts.